Rapid Epoxy - China Manufacturers, Suppliers, Factory

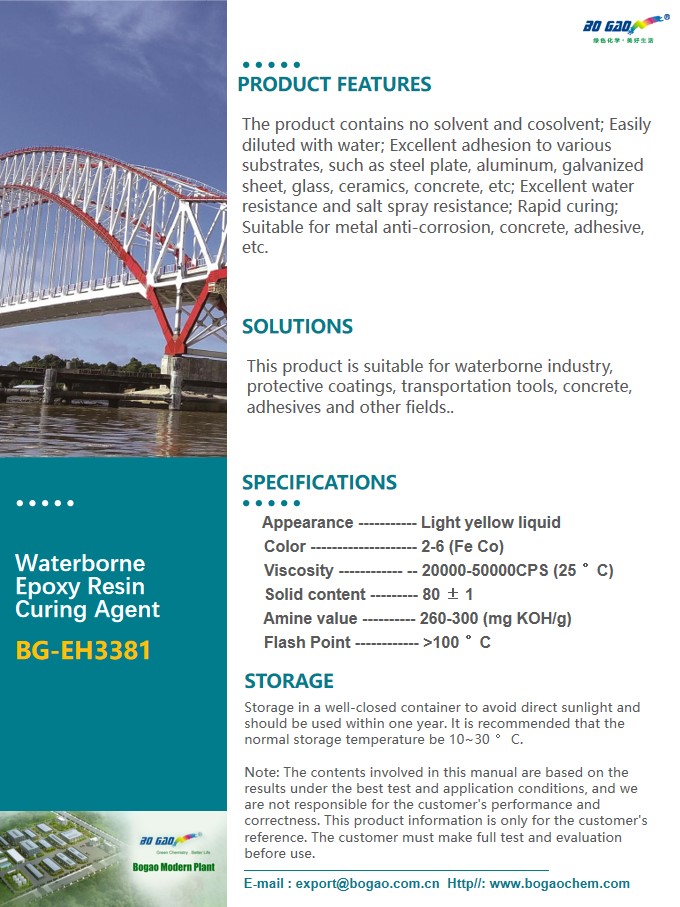

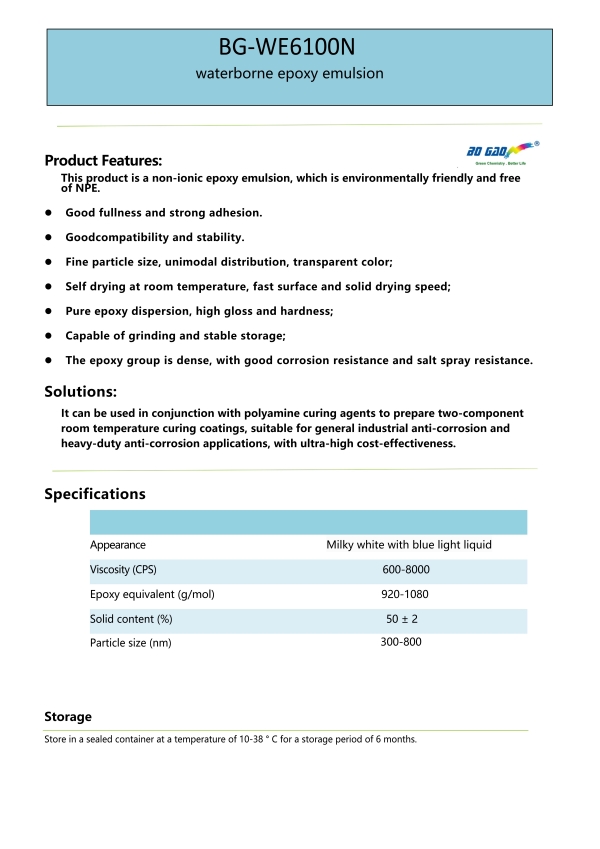

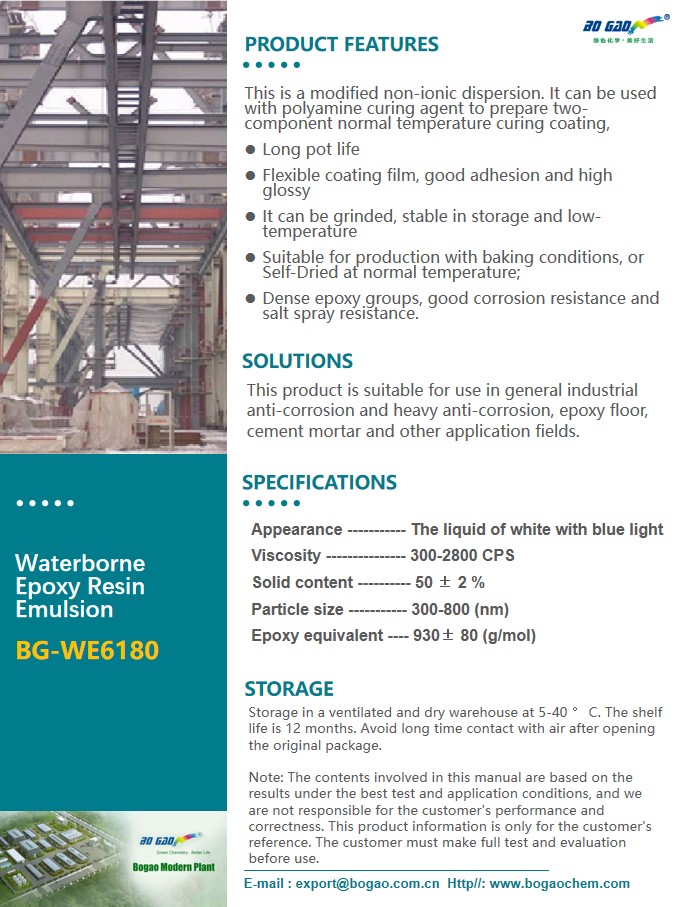

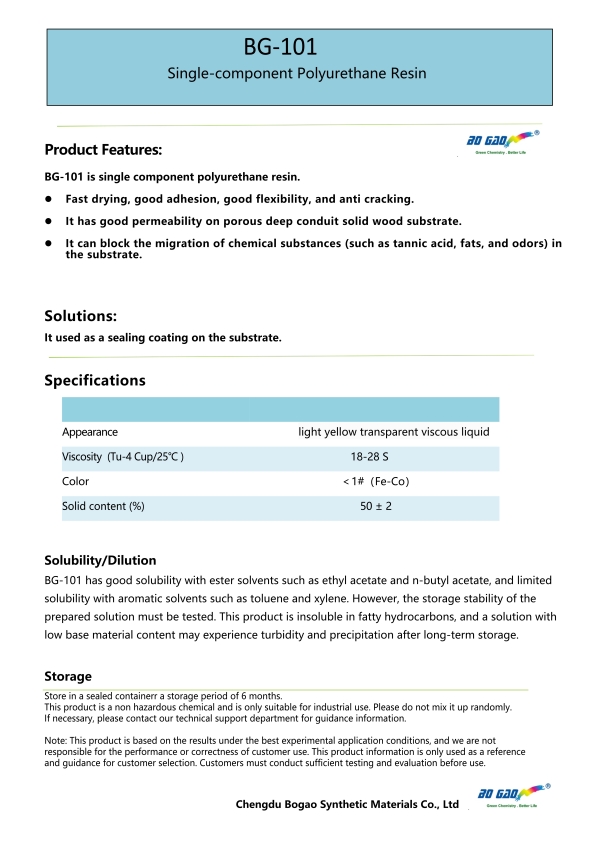

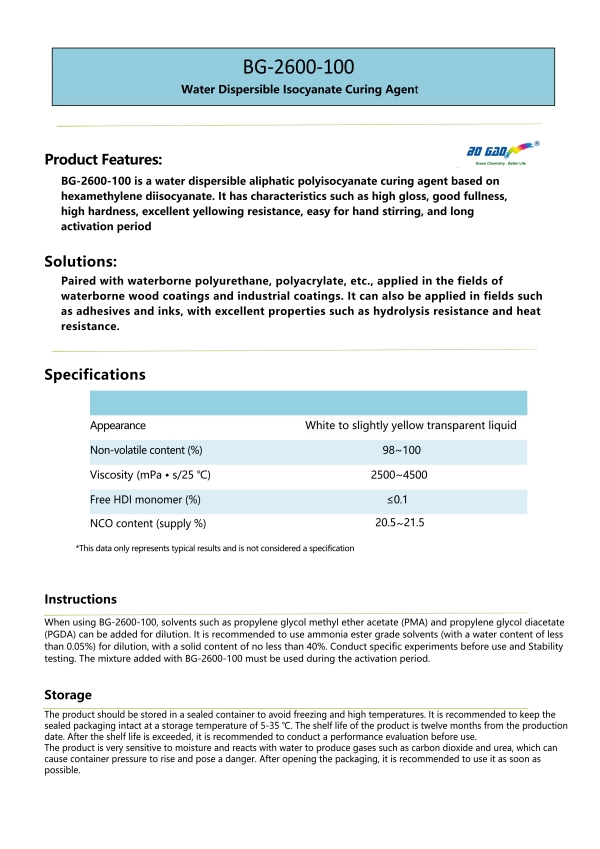

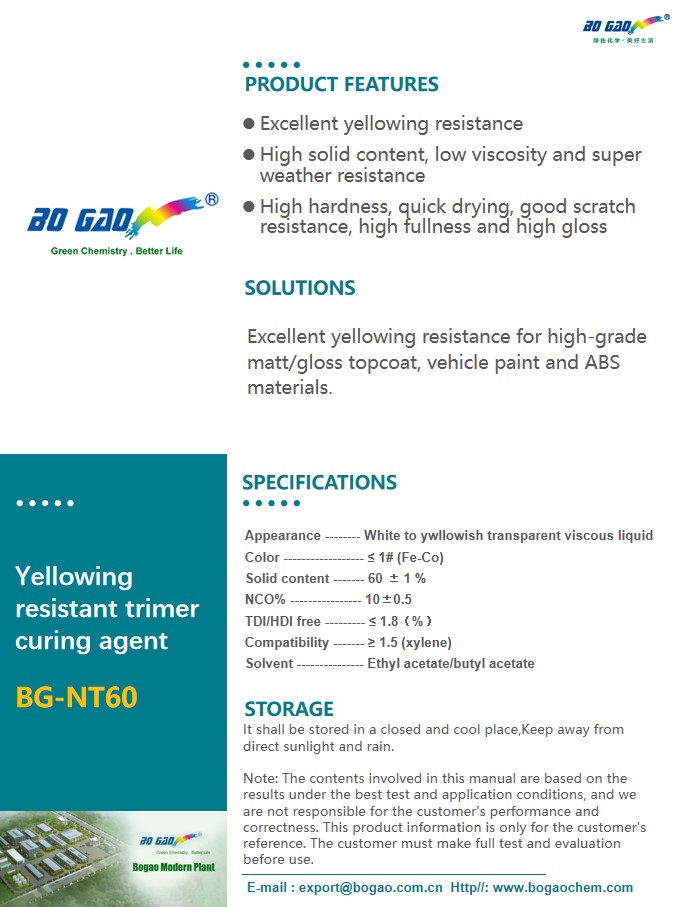

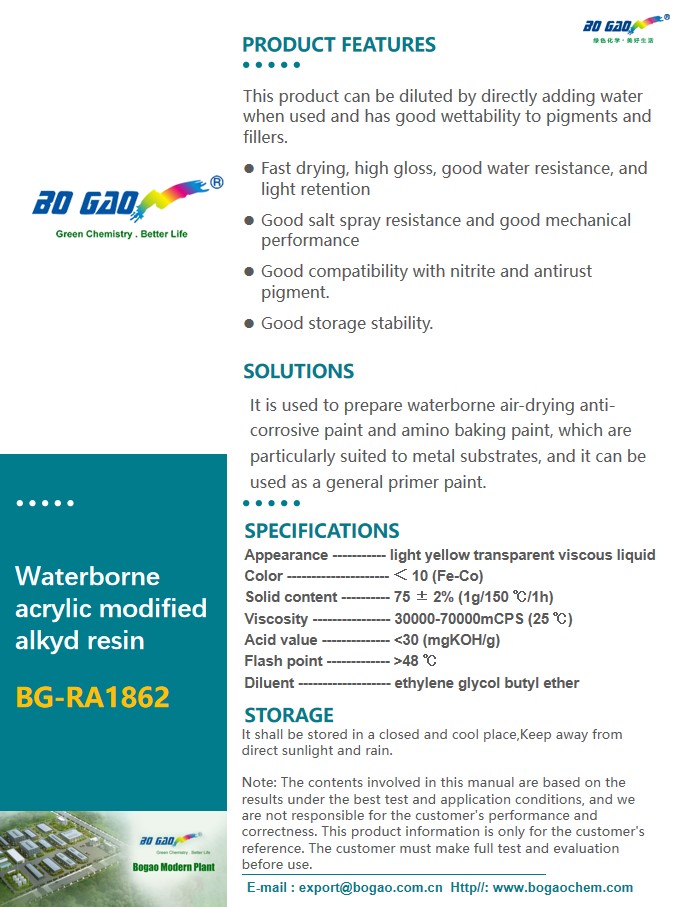

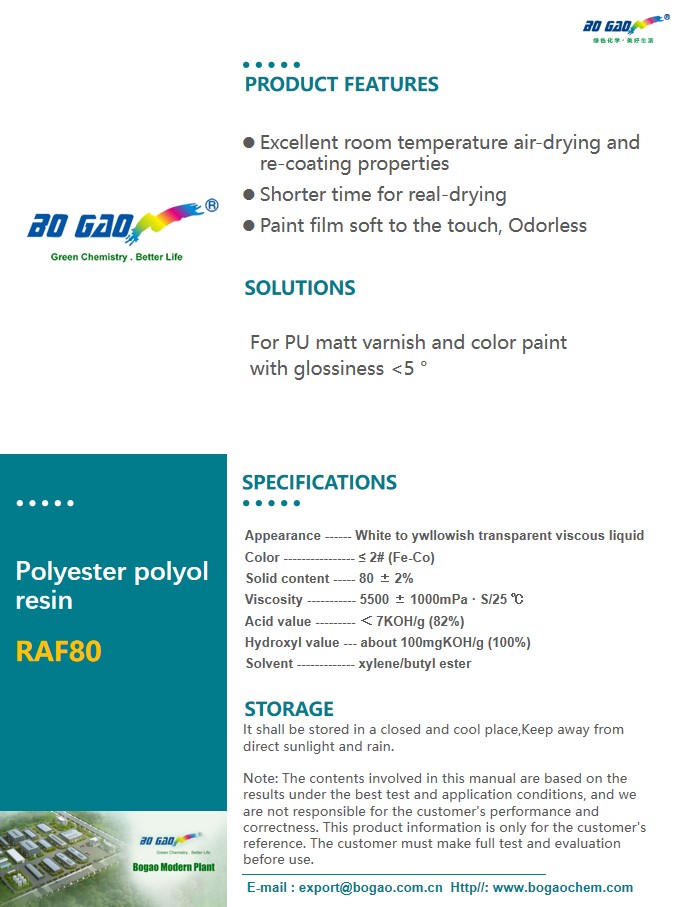

High-quality comes 1st; support is fore; business is cooperation is our small business philosophy which is regularly observed and pursued by our organization for Rapid Epoxy, Rail Transit Coating Resin , Adhesives Curing Agent , Bridging Agent For Adhesive ,Water-Soluble Acrylic Acid . NC paint, UV paint, and PU paint are the three main categories of domestic wood paint. All paint types have unique qualities, but PU paint is superior to other paint types in terms of environmental protection, adhesion, sealing, flexibility, and film transparency, making it an excellent option for wood paint used for house décor. The molecular features of PU paint film give it a high elongation at break and strong flexibility, which help to manage the film extension brought on by the floor's thermal expansion and cold contraction. After use, the film is difficult to break or peel off. PU topcoat is more abrasion and impact resistant than UV paint. PU paint provides excellent adherence to films,heavy impact resistance and abrasion resistance.For the covering, it offers good aesthetic and protecting qualities. It can also be used for some special PU paints with unique properties that are completely capable of painting sophisticated handicrafts, pianos, and even big airplanes. These paints can be used not only for flooring and woodwork in the home. Additionally, PU paint film has decent chemical resistance, resisting not only water but also acid, alkali, salt, as well as other home chemical cleaners, scratching, and corrosion. The building season is rather long since PU paint may be dried and cured at low temperatures, making a wide temperature range acceptable.Bogao is a professional manufacturer of PU curing agent for wood paint. The product will supply to all over the world, such as Europe, America, Australia,Toronto, Senegal,belarus, Wellington.Bogao is committed to developing and producing resins for high-performance waterborne coatings, developing new products of waterborne coatings, continuously introducing advanced new products of waterborne resins, meeting the film performance of industrial waterborne coatings, and improving the general problems of poor fast drying performance, easy water absorption after film formation, and insufficient mechanical properties of the film of waterborne coatings. The commonly used resins in waterborne coatings include waterborne polyurethane resin, waterborne epoxy resin, waterborne alkyd resin, etc.

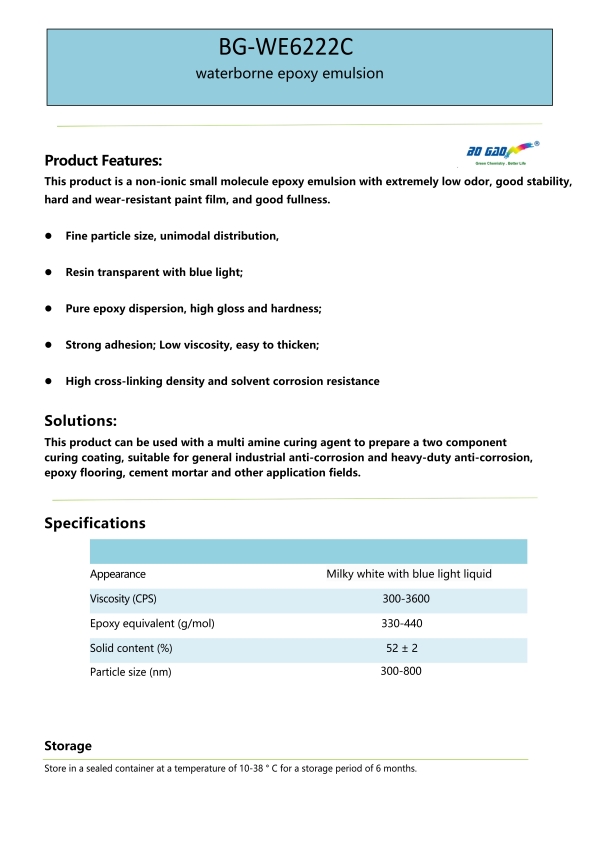

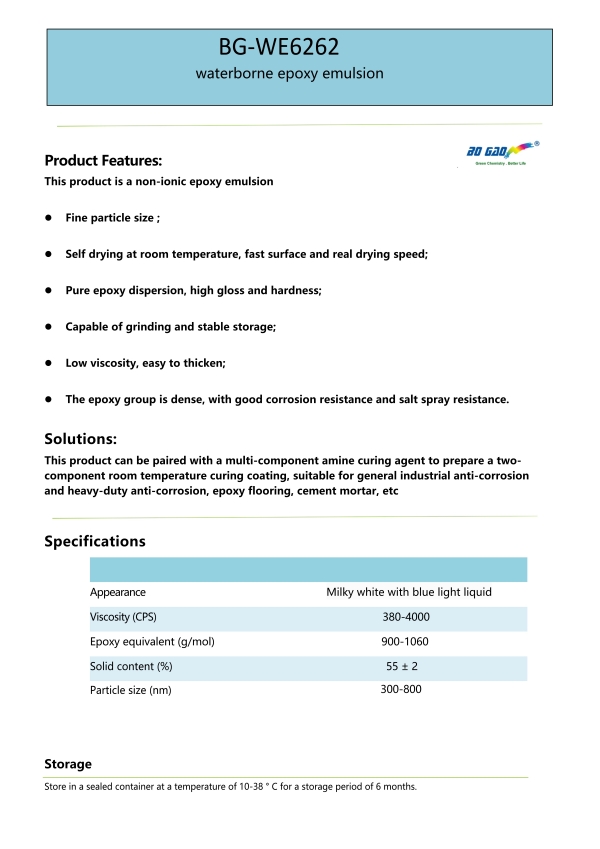

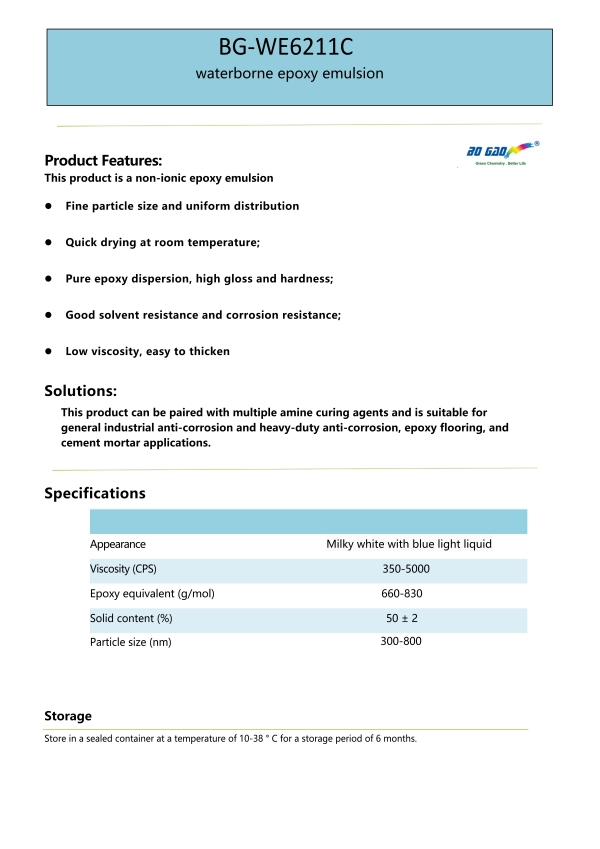

Related Products